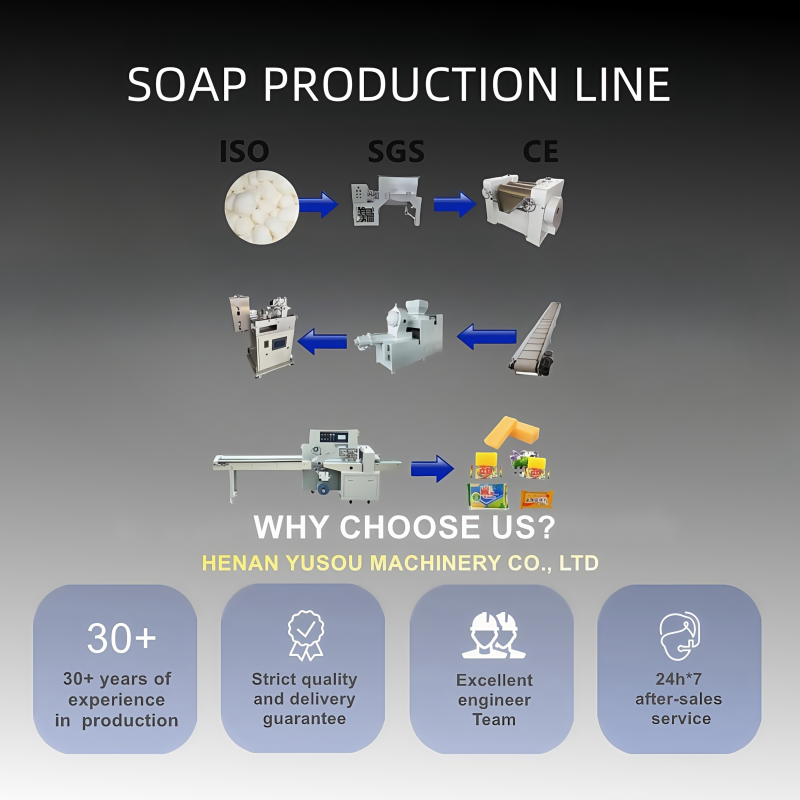

Soap Production Line

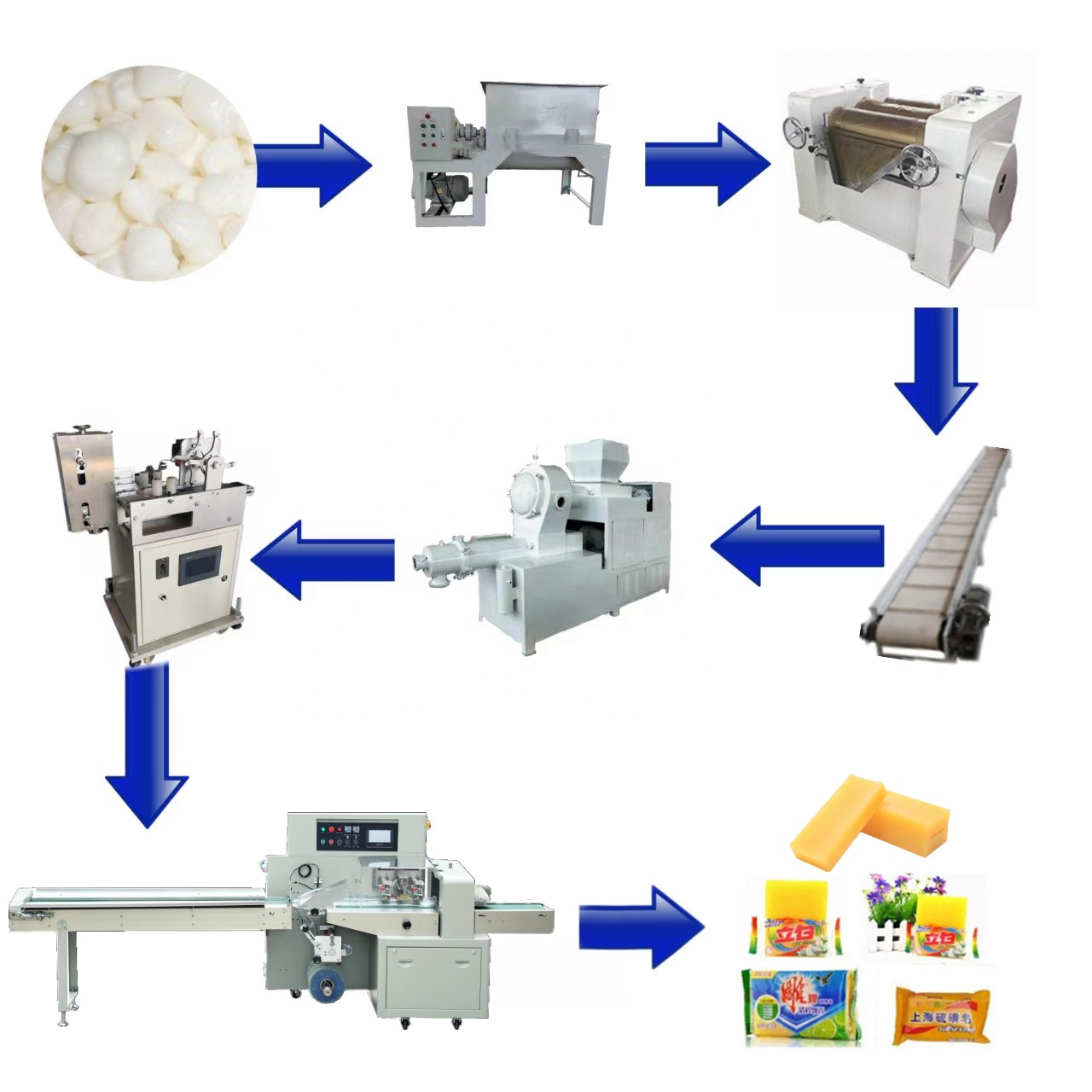

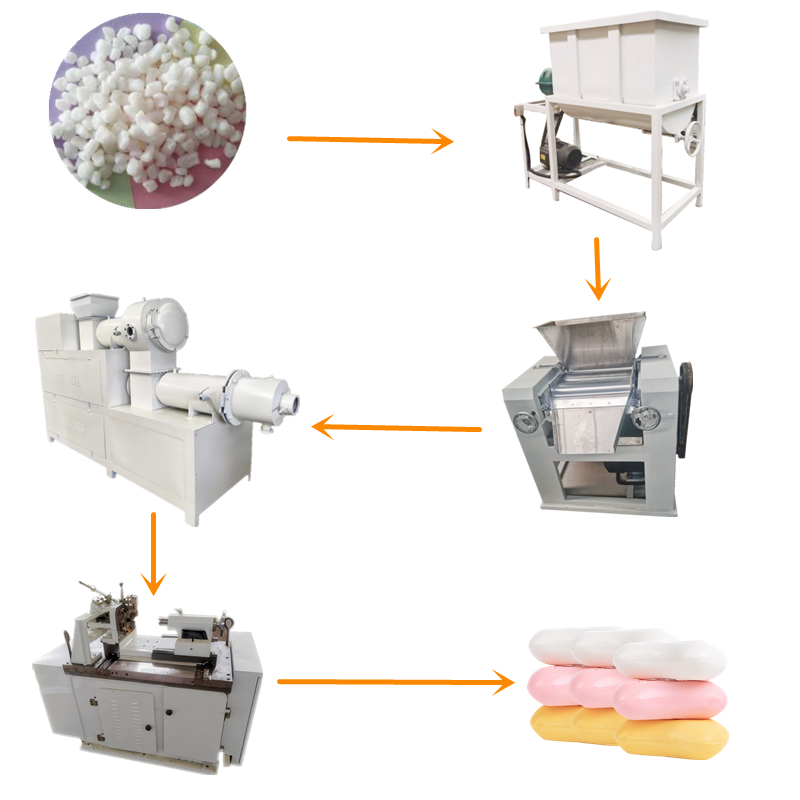

The soap production line is an industrial process specifically used to produce soap, which usually includes multiple links such as

raw material preparation, mixing, soap making, molding, and packaging.

Soap Production Process

1. Raw material preparation: Prepare the corresponding raw materials according to the type of soap required, including soap noodles,zeolite powder, liquid sodium silicate, fragrances, pigments, etc.

2. Mixing and grinding: Mix the soap grains with other raw materials in proportion. This step is the key in soap production and determines the quality and characteristics of the soap.

3. Soap cutting and printing: The mixed raw materials are ground and extruded to form a specific shape.

4. Soap Packaging: The molded soap needs to be packaged for easy storage and transportation.

Product Parameters

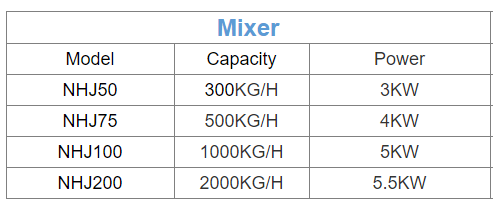

Soap Mixer

Used to mix various chemical raw materials

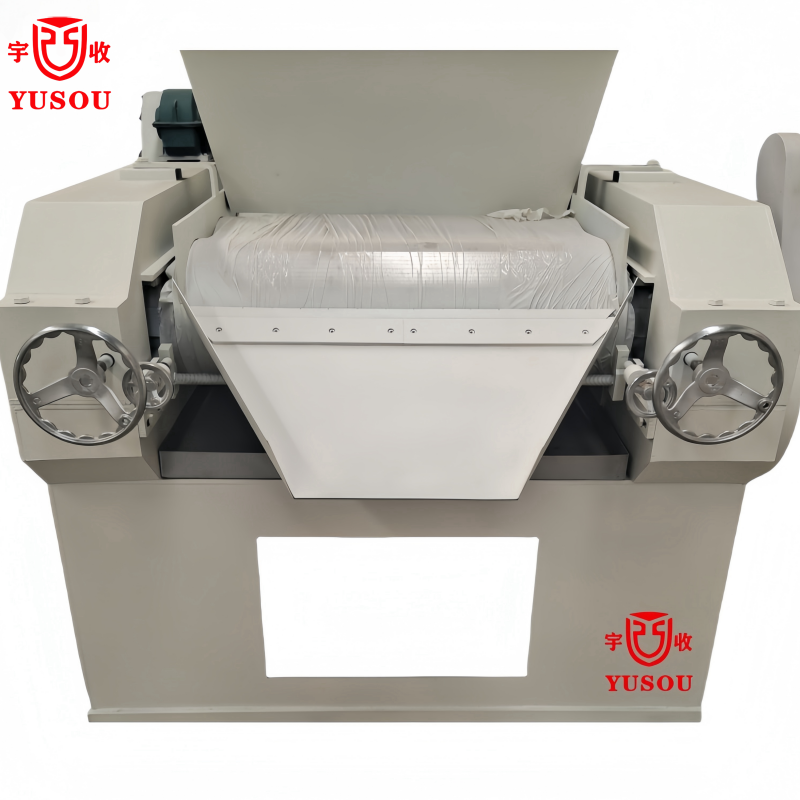

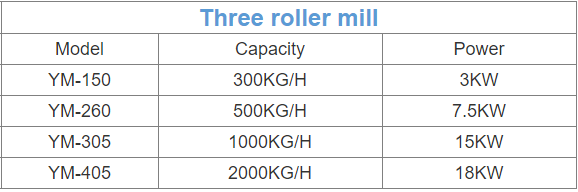

Three Roller Mill

Used for crushing and grinding raw materials

Soap Vacuum Plodder

Used for mixing raw material and extruding long bar soap

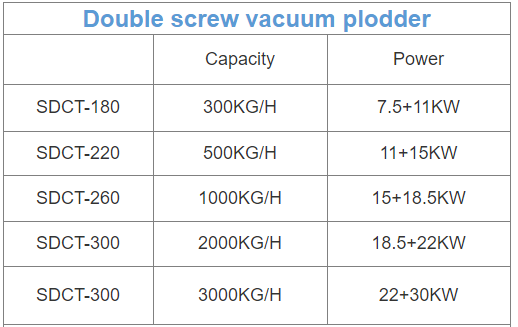

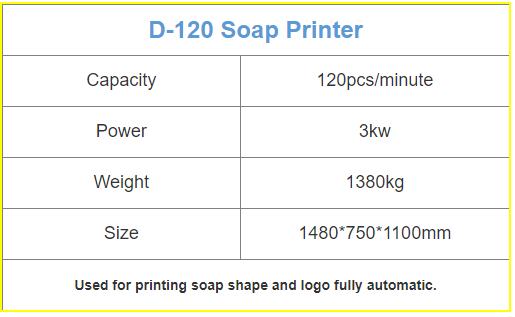

Soap Printer

Used for printing soap shape and logo fully automatic

Chiller

The Freezer adopts a fully enclosed refrigeration compressor, and the shell-and-tube heat exchange manufactured by computerized machine tool

and fully automatic welding technology is imported from the high-efficiency heat exchange copper tube. After being equipped with auxiliary equipment

such as a cooling water pump and cooling tower, the unit can provide frozen water from -20 °C to 0°C for users to use.

香皂、洗衣皂和透明皂的原料有二种来源:

一种采用棕榈油、牛油、猪油、椰子油、菜子油、豆油、棉子油等动植物油为主要原料,再添加纯碱、滑石粉等添加剂,制成皂粒投入生产。

另一种,用户可以直接购买皂粒,生产更为方便,且避免了三废产生。

本厂工程师经过多年的潜心研究,成功开发了一种适合家庭及中小型投资者使用的肥皂、透明皂工艺。

主要设备:皂化锅、真空干燥系统、皂粒机、拌料机、三辊研磨机、真空出条机、香皂打印机、冷冻机、输送带、控制柜等。

特点:

1.自动化生产,工作效率高;

2.一机多用、可生产多种规格的香皂、洗衣皂、透明皂。

There are two kinds of raw materials sources of laundry soap and transparent soap.

1. The invention relates to a kind of animal and vegetable oil such as palm oil, butter, lard, coconut oil, vegetable oil, soybean oil, cotton seed oil and other animal and vegetable oils as the main raw materials, and then adding additives such as soda, talc powder and so on, into production.

2.The users can buy soap directly, more convenient production, and avoid the production of wastes.

After more years of intensive research, our engineers have successfully developed a soap and transparent soap process suitable for families and small and medium investors.

Main equipment: saponification pot, vacuum drying system, soap granulator, mixing machine, three-roll grinder, vacuum plodder, soap printer, freezer, conveyor belt, control cabinet, etc. Characteristics:

1. automation production, high efficiency;

2. a machine multi-purpose, can produce a variety of specifications of soap, laundry soap, transparent soap.

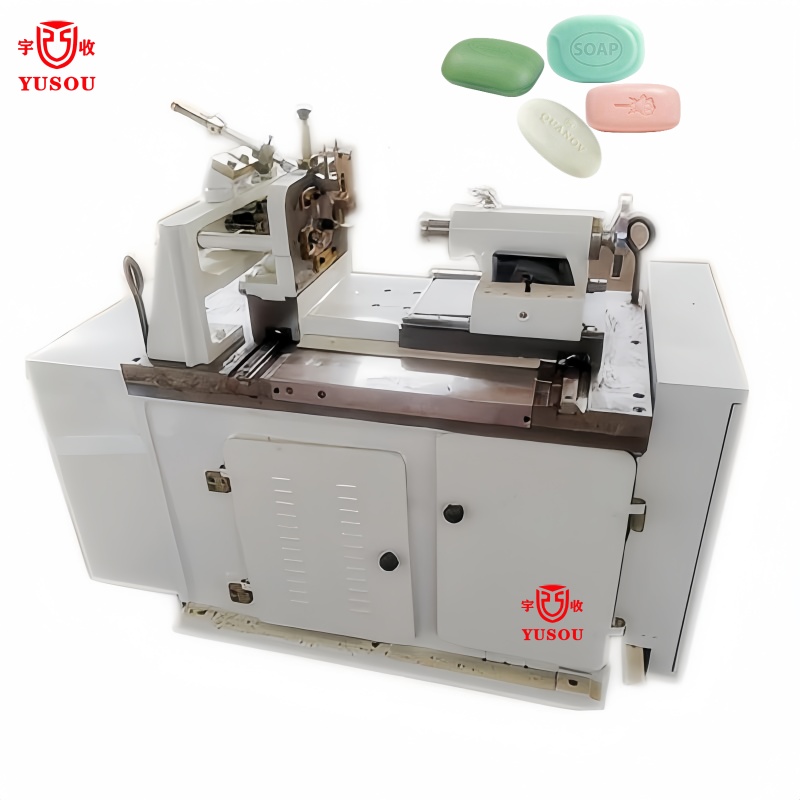

主要型号Main Models

型 号 model | SDCT-150C | SDCT-180C | SDCT-200C | SDCT-250C | SDCT-300C | SDCT-350C | |

产量Capacity(Kg/h) | 250-300 | 350-400 | 450-500 | 800-1000 | 1500-2000 | 2500-3000 | |

装机功率Power (kW) | 皂粒开始Start from Soap noodle | 20 | 25 | 30 | 45 | 55 | 75 |

Start from Oil and fat 皂化开始 | 30 | 40 | 50 | 65 | 85 | 100 | |