肥皂原料从油脂开始,一般经过以下工序。

1.皂化

油脂和碱反应,得到高级脂肪酸钠和甘油的反应(还有部分水),这个反应是制造肥皂流程中的一步。

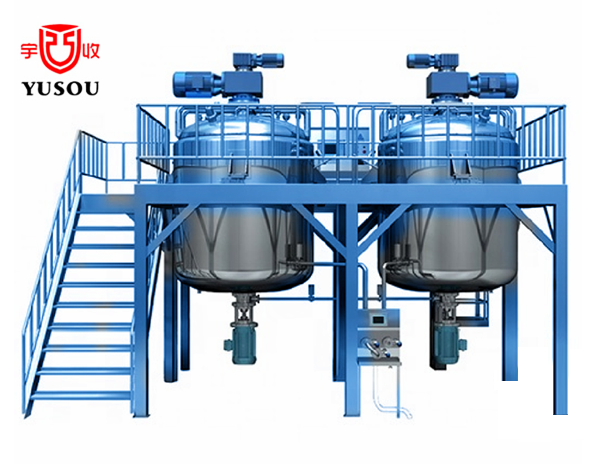

在皂化锅中,充分搅拌并加热,油脂层逐渐减少,***液体不出现分层,皂化反应完成。

2.盐析

在闭合的皂料中,加食盐或饱和食盐水,使肥皂与稀甘油水分离。使肥皂析出的较低浓度称为盐析***浓度。闭合的皂胶经盐析后,上层的肥皂叫做皂粒;下层带盐的甘油水从皂锅底部排出,以回收甘油。

3.洗涤

分出废液后,加水及蒸汽煮沸皂粒,使之由析开状态成为均匀皂胶,洗出残留的甘油、色素及杂质。

4. 碱析

为使皂粒内残留的油脂完全皂化,经碱析进一步洗出皂粒内的甘油、食盐、色素及杂质。碱析水完全析出的较低的碱的浓度称为碱析水***浓度。调整到足以使皂料析开成上下两个皂相。上层为纯净的皂基,下层为皂脚。皂脚色泽深,杂质多,一般在下一锅碱析时回用。

Soap raw materials from the oil & fats, generally through the following procedures.

1. saponification

The reaction of oil and alkali to sodium and glycerol (and some water) is a step in the process of making soap.

In the saponification pot, the oil layer is gradually reduced and the saponification reaction is completed.

2. salting out

In closed soap, add salt or saturated salt water to separate soap from dilute sweet oil. The lower concentration of soap precipitation is called salting out * concentration. After salting out the closed soap glue, the upper soap is called soap grain; the lower layer of glycerol with salt is discharged from the bottom of the soap pot to recover glycerol.

3. washing

After separating out the waste liquid, add water and steam to boil the soap particles, so that it can become uniform soap glue from the open state, and wash out the residual glycerol, pigment and impurity.

4. Alkaline Analysis

In order to completely saponify the residual oil in the soap, glycerol, salt, pigment and impurities in the soap were further washed out by alkali analysis. The lower concentration of alkali precipitated completely is called alkali precipitated water concentration. Adjust enough to separate the soap into two soap phases. The upper layer is pure soap base, the lower layer is soap foot. Soap foot color deep, more impurities, generally in the next pot of alkali precipitation reuse.

产量Capacity:0.5TPD -500TPD